Champion H&C Inc. is an aluminum die casting components supplier that has been producing a variety of zinc die casting parts for over 30 years. Die-cast aluminum alloys are lightweight, offer high dimensional stability and are suitable for complex part geometries and thin walls. Aluminum has good corrosion resistance, mechanical properties, high thermal and electrical conductivity, making it a good alloy for die casting. The aluminum die-casting process requires the use of cold chamber machines to maintain long-lasting strength at very high temperatures. The molten metal is in an open thermos, which is placed into a furnace where it is melted to the desired temperature. The open holding tank is separate from the die casting machine and the molten metal is scooped out of the holding tank for each cast, as the high temperatures can damage the normal pumping system. Cold chamber castings generally have higher pressure requirements than hot chamber die castings.

Key Advantages of Aluminum die-casting:

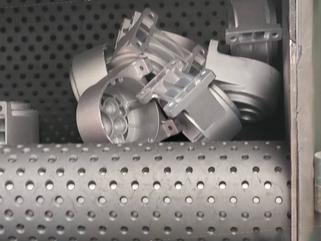

AN ALUMINUM DIE CASTING MANUFACTURER & PRECISION ALUMINUM PARTS COMPANY

Champion presses range in size from 250 ton to 1100 ton producing aluminum die casting components for low and high volume production programs. Champion provides high pressure die casting and a range of other die casting processes. Process monitoring, press side imaging, robotics, perpetual tooling, and tool maintenance programs are utilized to extend tool life, reduce cycle times, reduce costs, and provide high quality die castings. From precision aluminum parts manufacturing and prototyping through assembled finished production, PHB can provide, under one central umbrella, the integrated services required to be your complete global manufacturing resource.

ALUMINUM ALLOY DIE CASTING

Aluminum die casting alloys are lightweight and possess high dimensional stability for complex part geometries and thin walls. Aluminum has good corrosion resistance and mechanical properties as well as high thermal and electrical conductivity, making it a good alloy for die casting.

Our Alloys Include:

ALUMINUM SURFACE FINISHING

Champion will manage customer finishing requirements to ensure parts meet specifications in both a timely and cost-effective manner.

Our aluminum surface finishing includes, but is not limited to:

How does Champion aluminum die casting workshop work?

For more details about aluminum die casting products, try to check out below: